Breakthrough AI System Accelerates Robotic Pick-and-Place Operations

Robots have long been ideal candidates for repetitive warehouse tasks like pick-and-place operations, yet humans still outperform them in speed and adaptability. Now, researchers at UC Berkeley have developed an innovative AI solution that could bridge this gap—reducing robotic decision-making time by an astonishing 99%.

The Human Advantage vs. Robotic Limitations

For humans, picking up an object and placing it elsewhere is second nature. Our brains intuitively calculate efficient paths and adjust grips without conscious thought. Robots, however, lack this innate spatial reasoning. They must:

- Evaluate thousands of potential movement paths

- Calculate force requirements and collision risks

- Determine optimal grip configurations

- Process all variables sequentially

While execution is swift once a decision is made, the planning phase can take seconds—or even minutes—in complex environments.

The Berkeley Breakthrough: Dual AI Architecture

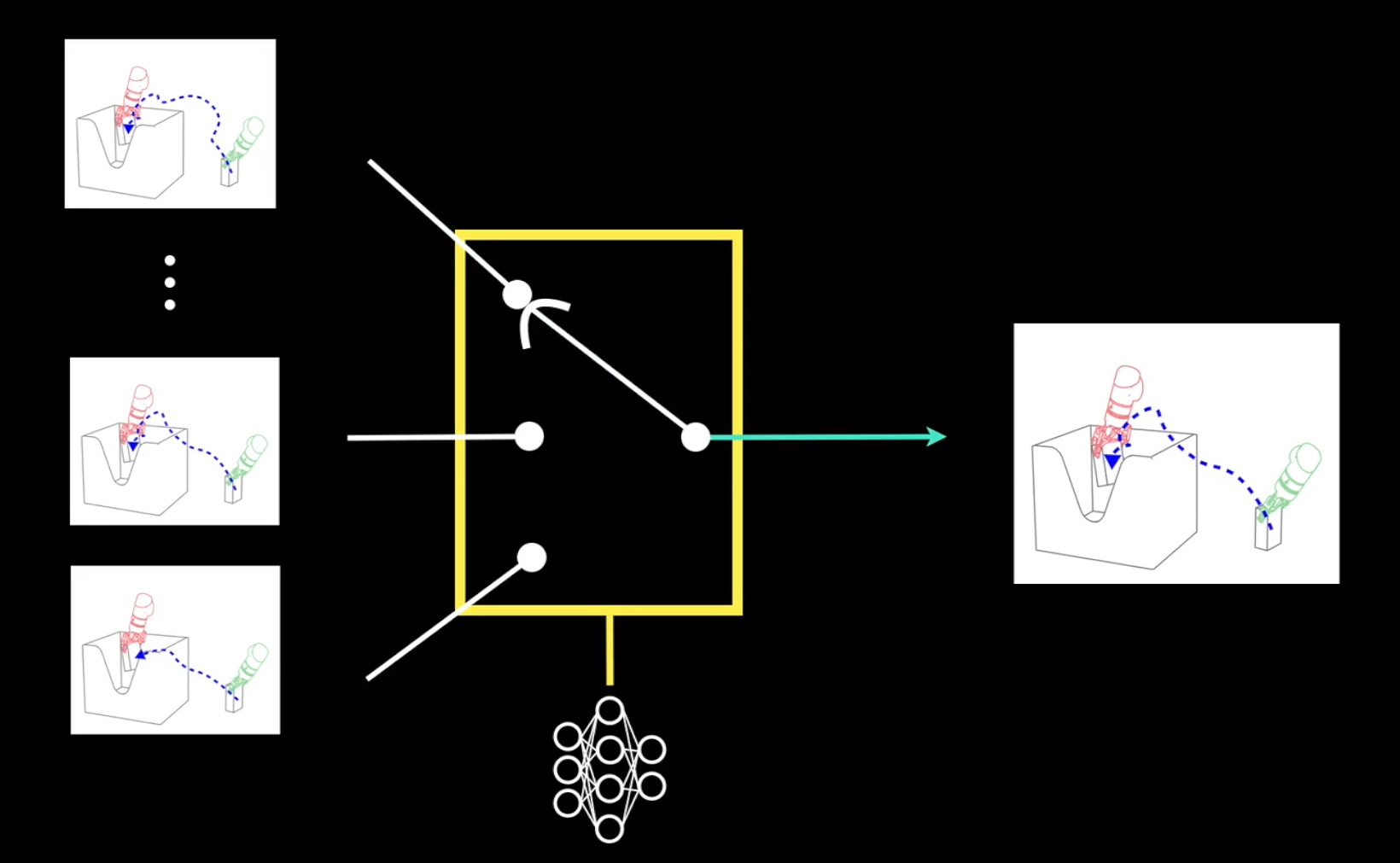

The UC Berkeley team’s solution employs two specialized machine learning models working in tandem:

- Path Generator: Rapidly produces multiple potential movement options (trained on extensive motion datasets)

- Path Selector: Chooses the most optimal path from generated options

This AI pair provides a “warm start” to traditional motion planners, which then refine the selected path. The result? Planning times plummet from 10-40 seconds to under 0.1 seconds in controlled tests.

Visualization of the dual-AI decision process (Source: UC Berkeley)

Visualization of the dual-AI decision process (Source: UC Berkeley)

Real-World Impact on Warehouse Operations

While laboratory results are impressive, real warehouse environments present additional challenges. However, even reducing planning time from 2-3 seconds to near-zero creates substantial efficiency gains:

- Potentially doubles robotic pick rates

- Reduces system idle time by up to 50%

- Complements advancing computer vision capabilities

“Every second counts,” emphasizes Ken Goldberg, the lab’s director. “Current systems spend up to half their cycle time on motion planning, so this method could dramatically increase picks per hour.”

The Future of Automated Warehousing

Though robots still trail human workers in overall efficiency, this advancement represents a significant leap forward. As Goldberg notes, incremental improvements in:

- Motion planning

- Computer vision

- Gripping technology

will eventually make robotic systems not just competitive, but superior to human workers—particularly valuable in dangerous or physically demanding roles that currently employ millions worldwide.

The research was published in Science Robotics and marks another step toward fully automated, high-efficiency warehouse operations. As e-commerce continues expanding, such innovations will prove increasingly vital to meeting global logistics demands.